In This Issue

TECHNICAL PUBLICATION #33

MODERN COAXIAL LIGHTNING ARRESTORS: POLYPHASER VS. I.C.E.

This is a comparison report between coaxial cable lightning arrestor units manufactured by Polyphaser

Corp. and Industrial Communication Engineers, Ltd. Both companies manufacture a wide variety of such

protective devices and are sold worldwide. Each of the designs described in this report is protected. by

patents issued by the U.S.- Bureau of Patents and Trademarks in Washington, D.C.

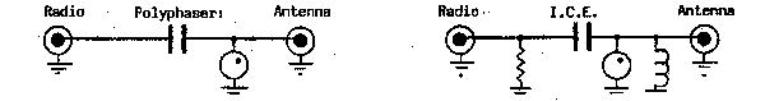

Although - there, are . some subtle variations. in, the product line, Polyphaser's basic coaxial line layout is.

basically a two component system. As shown in the schematic below, a high-voltage rated capacitor is

used as a central blocking device to permit the unimpeded flow of RF currents through the arrestor while

blocking DC voltages and low frequency AC voltages from passing through the arrestor while blocking DC

voltages and low frequency AC voltages from passing through the device to reach station equipment. A gas

discharge assembly having a breakdown voltage rating in the 400-1,000 volt range is used for transmitting

services so that when a difference of potential between the conductors reaches this amount on the antenna

side of the polarized unit the gas discharge unit ignites, shunting the voltage surge to ground.

While this is certainly a workable arrangement and the Polyphaser units are well built, we concluded in our

engineering studies that there were significant limitations to the design. Among them:

1) No constant drain mechanism is provided in the Polyphaser design. A coaxial line acts often like a large

capacitor, storing electrical charge that can only leak off the line through antenna joint connections or

through the dielectric, nearly always causing receiver "hash" noise during electrical activity.

2) The use of a gas discharge unit as a sole-source mechanism for neutralizing lightning currents delivered

by heavy coaxial line conductors is controversial. Gas units have only a small dissipative power rating,

seldom exceeding 1 watt. While the devices can handle large jolts of thousands of amperes of current, they

can perform that service only if the entire impact event lasts only a few microseconds. Lightning currents,

especially slowed down by time constants due to the inductance of transmission lines are much slower to

begin, endure, and end. The result is rupture and failure of gas discharge units, requiring frequent

replacement and down time.

3) It is very difficult to determine the condition of a gas discharge unit, especially after it has taken a few

"hits." They don't always go short circuit.

The I.C.E. design, also shown below, took these characteristics into account during development and

testing. We also use a central high voltage blocking capacitor, but with a large discharge inductor on the

antenna side as a primary neutralizing agent. Any voltage development is quickly shunted to ground

through the DC shorting nature of the inductor/RF choke. If large currents of a fast rising nature,, are

presented to the arrestor in such a way that a back-EMF develops across the inductor then the companion

paralleled gas discharge unit ignites, but its only workload is to collapse the magnetic field of the inductor.

The result is an arrestor whose gas unit undertakes such a low workload that is will probably last forever.

To date no replacement gas units have been sold by us. The added resistance on the equipment side of

the arrestor was inserted to provide a similar drain function on the user side of the arrestor. I.C.E. uses a

four part system. ©

CBWI

© CB World Informer Network 1996 - 2023 Worldwide Rights Reserved

AUGUST

VOLUME 1

ISSUE 7

- August 1996

- September 1996

- October 1996

- November 1996

- December 1996

- Review Of Midland 79-290 AM/SSB Mobile

- Cobra/Uniden SSB Chassis Mod UPDATE

- Clarifiers

- President Jackson Unlocked Clarifier Mod.

- Cobra 148 & Uniden GrantXL Clarifier Mod.

- Cobra 142GTL & Uniden Washington Clarifier

- Uniden Grant Unlocked Clarifier Mod.

- Uniden PCI22 PRO SSB Clarifier Mod.

- Review Of The Northstar DX880HL

- Big Bust At The Consumer Electronics Show

- Bob's CB Has Opened

- January 1997

- The New Mongoose Model 450 Review

- Wilson Antenna Tests The Trucker 5000

- A Company With Interference Solutions

- Solving Telephone RF Interference

- Lowpass Filters: What, Where, And How

- Using Highpass Filters For TVI

- How To Conduct A Noise Audit

- Modern Do-It-Yourself Grounding Techniques

- Using Water Pipes For RF Grounding

- Using Water Pipes For RF Grounding

- February 1997

- The New Emperor TS-3010 Review

- Bulkhead Grounding

- Grounding Coaxial Cable Shields

- Using Anti-Oxidants

- Modern Lightning Protection - RF Entry Ports

- Modern Lightning Protection - AC Power Lines

- Modern Lightning Protection - Control Lines

- Modern Lightning Arrestors - Polyphaser VS I.C.E.

- Modern Lightning Arrestors - Alpha Delta VS I.C.E.

- Modern Lightning Arrestors - Cushcraft VS I.C.E.

- July 2001

- Galaxy DX 2547 Reveiw

- Inside The DX 2547

- DX 2547 Channel Mod

- DX 2547 Clarifier Mod

- DX 2547 Photos

- DX 2547 Manual Excerpts

- The Anttron Story

- Anttron 305 Revisited

- New Antrron Products

- Aries A-SWR 460 Digital Meter

- Barjan Buys Wilson Antenna

- Wilson Electronic In Cell Phone Market

- First Web Issue

- Help Get The Word Out

- August 2001

- Sneak Preview: The New Maverick A24

- Maverick A24 Front Panel Controls

- Maverick Conversion

- Inside The Magnum Maverick A24

- Barjan Buys Francis Antenna

- Wilson Antenna, 1 Year After Barjan Buyout

- CBer Busted

- Astaic's MobileMax

- Solarcon I-Max 2000

- False Performance Claims

- CAUTION: Don't Burn Out That Radio

- Magnum's Filtered Power Cord

- Dragon Super Heavy Duty SO-239 Stud

- CBWI...Give Us Your Opinion

- September 2001

- Reveiw Of The RCI 2950DX

- RCI 2950DX Image Rejection Modification

- RCI 2950DX Coversion & Clarifier Mods

- RCI 2950DX Photos

- RCI 2950DX Board Component Layout

- RCI 2950DX Adjustment Layout

- RM-9807: Petition To Remove 155 Mile Limit

- Slip-Seat Radio Box

- RF Limited UTB-1 Adjustable Talkback Board

- A Message From The Editor

- October 2001

- November 2001

- December 2001

- January 2002

- February 2002

- July 2002

- June 2014